While Disney-Pixar’s film Finding Nemo tells a fantastic story involving a father fish, his son, and the ocean, Nemo’s lucky that the plot of the film didn’t involve him being flushed down a toilet in a suburban home. If it had, Nemo would’ve undergone a crucial Odyssey before even reaching a river: he would’ve journeyed through a municipal wastewater treatment plant. While a jaunt through a municipal wastewater plant doesn’t sound as commercially attractive as adventuring through the ocean, the purity and quality of municipality waterways and their ecosystems depends on municipal wastewater plants’ implementation of standards through treatment, via an air-tight water purification process.

The goal of a municipal wastewater treatment plant is to act as a gateway between contaminated wastewater and the water sources where the wastewater eventually goes. For that reason, many wastewater treatment plants are built in low-lying areas, usually with easy to access to water sources, such as river. All the water which leaves the plant after processing, called the ‘effluent’, needs to meet a standardized level of quality. The Environmental Protection Agency (EPA) estimates that there are around 16,000 municipal treatment plants active in the U.S. today; all of them need to meet the same environmental requirements in terms of their treatment quality.

The primary treatment in the process utilized by municipal plants reduces solid objects and suspended solids in the water via a barrier – otherwise known as sedimentation. Nemo, unfortunately, probably wouldn’t’ve made it past here. The process aims to reduce the presence of solid objects, pathogenic (disease causing) bacteria, biodegradable organics (BOD’s), and excess nutrients found in the wastewater. Primary, or mechanical, treatment filters the solid objects, while secondary treatment focuses on biological elements of the water. According to the World Bank Group, 85% of BODs and associated solids are eliminated by the conclusion of secondary treatment, which correlates with the EPA’s standards and their emphasis on plants having thorough, precise, and controlled secondary treatment systems. Tertiary treatment systems are becoming more popular in plants, as the advancement of technology leads to an even more robust cleanliness demand. Especially at the tertiary level, valves are essential because computer-based instrumentation can open, close, and/or partially close valves to ensure that purification is correlating with process control.

The process controllers use level and pressure measurement instruments to evaluate the quantitative and qualitative aspects of the wastewater. The pressure and level sensors indicate that the treatment systems are functioning properly, but also that the water moves from station to station in the plant with the most efficiency and care. If the instrumentation being monitored by plant employees is incorrect, a glitch in the system could lead to a decrease in the quality of the effluent water, resulting in damage to the environment. The process technology and its controllers must be both automatically and manually sound, because reliable operators need a reliable system to produce a top-quality result.

Sorry, Nemo, the sequel isn’t taking place in a municipality anytime soon!

Educational information on process control, industrial instrumentation, valves, valve automation and control valves. For additional information visit IvesEquipment.com or call 877-768-1600

Showing posts with label New Jersey. Show all posts

Showing posts with label New Jersey. Show all posts

Monitoring Interface Between Compounds in a Pipeline

|

| Applied Analytics™ OMA |

Since the pigs are never completely effective at blocking the interface, a significant volume does suffer intermixing and must be removed for reprocessing. The amount of material routed to reprocessing is usually just pre-programmed with a large margin of error on either end of the interface to ensure removal of intermixed products. This is a simplistic model that is unnecessarily wasteful of material and time.

By using a device such as the Applied Analytics™ OMA industrial analyzer, the chemical concentrations, purity, and physical properties can be measured in a continuously drawn sample from the liquid stream. This allows for real-time analytics of the materials in the pipe, including chemical concentrations, purity, and color.

The OMA system continuously monitors full-spectrum absorbance in the pipeline stream. A change in this spectrum indicates a change in the purity/composition of the material passing through the pipeline. Therefore, the OMA immediately detects the ‘interface’ point where the material has begun to intermix with the subsequent material in the pipeline.

Monitoring the 1st derivative of a complete UV-Vis/SW-NIR absorbance spectrum allows the OMA to detect changes in composition with high sensitivity and fast response. The user can define the threshold contamination level which will signal for rerouting of the stream.

For more information, contact Ives Equipment at http://www.ivesequipment.com or call (877) 768-1600.

Flow Meter for Efficient and Cost-effective Use of Water for Irrigation

|

| Irrigation flow meter in the field (courtesy of SIEMENS) |

Few resources are as vital to the human population, and the global economy as water. To ensure the continuous preservation of this valuable commodity, the water industry has

|

| On-site testing and validation via SIMATIC PDM tool. |

Features to be considered for irrigation flow meters:

- Battery-powered for greater flexibility in the field

- Accuracy

- Maintenance-free operation

- Tamper-proof and robust

- Flexible communication

- Qualification certificate

- Wireless solution

Benefit of the SITRANS F M MAG 8000

- Simple meter placement - floating chamber IP 68 (NEMA 6P) design ensures continuous filterless performance regardless of position or in-line piping stresses, even when buried underground

- Low pressure loss - unrestricted flow tube ensures minimal pressure loss even at high flow rates and reduces overall network system pressure, helping to prevent leakage from burst pipes and excess stress placed on pumping stations

- Zero maintenance – no moving parts and 10-year battery life

- Bi-directional measurement - only one meter required for measurement in both directions

- Installation requires 0D inlet to and outlet from the sensor - eliminating concerns about where the meter is installed

- Intelligent meter – capable of leak detection, data logging and error self-detection

- Remote capabilities – stay up-to-date on measurement data without having to visit the site through optional GSM/GPRS Wireless Communication Module

For more information, contact Ives Equipment by visiting http://www.ivesequipment.com or calling (877) 768-1600.

Labels:

Delaware,

MAG 8000 Irrigation,

Maryland,

New Jersey,

New York,

Pennsylvania,

Siemens,

Virginia

Special Application Challenges Call For High Performance Butterfly Valves

|

| Series 400 High Performance Butterfly Valve ABZ Valve |

Industrial valves intended for extreme applications are generally referred to as severe service or high performance valves. While there are plenty of published and accepted standards for industrial valves, one does not exist to precisely define what constitutes a severe service valve.

So, how do you know when to focus valve selection activities on severe service or high performance valves, as opposed to those rated for general purpose? There are a number of basic criteria that might point you in that direction:

- Extreme media or environmental temperature or pressure

- High pressure drop operation that may cause cavitation

- Rapid or extreme changes to inlet pressure

- Certain types or amounts of solids contained in the fluid

- Corrosive media

Certainly, any of these criteria might be found in an application serviceable by a general purpose valve, but their presence should be an indicator that a closer assessment of the fluid conditions and commensurate valve requirements is in order. The key element for a process stakeholder is to recognize when conditions are contemplated that can exceed the capabilities of a general purpose valve, leading to premature failure in control performance or catastrophic failure that produces an unsafe condition. Once the possibility of an extreme or challenging condition is identified, a careful analysis of the range of operating conditions will reveal the valve performance requirements.

There are numerous manufacturers of severe service or high performance valves, each with specialized product offerings focusing on a particular performance niche. ABZ Valve manufactures high performance butterfly valves ranging from 2-48 inches and 150-600 psi. The valve design is ideal for manual or automated actuation, installed with a manual hand gear, electric actuator, or a pneumatic actuator. Seats are available as soft, metal, and fire safe, and body types include wafer, double flanged, and butt-welded. Construction materials include carbon steel and 316 stainless steel. A range of options and variants are available to customize the valve build to suit a replacement or new installation.

More information about the ABZ Valve high performance offering is included below. You can always get more information and discuss your special requirements with a valve specialist. They have application experience and access to technical resources that can help with selecting the right valve components to meet your severe service and high performance applications.

A Proven Ultrasonic Level Transmitter for Environmental, Water/Wastewater, and Energy Management Industries

|

| Reliable level control for environmental applications SITRANS LU150/180 |

Designed primarily for liquid applications in the environmental, water/wastewater, and energy management industries, the device is ideal for non-contact continuous level measurement of liquids and slurries in open or closed vessels.

The reliability of the level readings are based on Sonic Intelligence echo processing algorithms that Siemens has been refining for decades. These algorithms differentiate the true material level echoes from the false ones that can result from acoustic or electrical noises, as well as from agitator blades in motion. It's effective, accurate, unique, and it's exclusively Siemens.

Key Applications

- Chemical storage vessels

- Filter beds

- Mud pits

- Liquid storage vessels

- Food applications

For more detailed information, check out the brochure below:

Industrial pH Control Basics

|

| pH sensor courtesy of HF Scientific |

|

| pH display courtesy of HF Scientific |

Accurately applying the correct amount of reagent to an acid or base solution can be challenging due to the logarithmic characteristics a pH reaction in a solution. Implementing a closed-loop control system maintains the pH level within a certain range and minimizes the degree to which the solution becomes acidic or alkaline.

An example of an automatic pH level control system is a water treatment process where lime softened water is maintained at a pH of 9 using carbon dioxide as a reagent. As the untreated water (or influent) enters the tank, the pH is continuously monitored by the pH sensor. The sensor is the feedback device to the controller where the setpoint is compared to the control value. If the values are not equal, the controller sends a signal to the control valve that applies carbon dioxide to the tank. The reagent is applied to the tank at varying rates to precisely control the pH level. With the pH level at 11 detected by the sensor, the controller commands the control valve to open and introduce more carbon dioxide. As the increased carbon dioxide mixes with the influent, the pH is lowered in a controlled manner. Reaching the setpoint, the carbon dioxide flow is minimized and the process is continually monitored for variation. The effluent is the treated water that is discharged out of the tank. The process continues to provide the lime softened water at the desired pH level.

Labels:

control,

Delaware,

HF Scientific,

Maryland,

New Jersey,

New York,

Pennsylvania,

pH,

Virginia,

wastewater treatment,

water

Process Equipment Corrosion / Materials Compatibility Guide

|

| Make sure your equipment is compatible with your process! |

This chart is a guide to the engineer in the selection of materials for corrosive services. No one material can be expected to handle the wide variety of corrosive media found in industry today. Therefore, the user must decide, based on experience, which properties are of prime importance in their application.

The process equipment in contact with the media should carry an A Rating. This chart is intended to be a guide, and if any questions exist on the application of a material, actual tests should be performed to determine the suitability of the material. When in doubt, ALWAYS consult an application expert.

Simple Ways to Maximize the Efficiency of Your Process Control Application White Paper

|

| Siemens Integrated Drive Systems |

A white paper courtesy of SIEMENS

No matter what industry you’re in, the price of your inputs is bound to fluctuate – usually trending in a direction that doesn’t favor profits. You can’t control the rising costs of raw materials and energy, but you can control how much you get out of them. The simplest way to do this is by maximizing the efficiency of your equipment.

Performance and productivity are directly related to energy use, reliability and maintenance costs. The improved performance offered by a highly efficient drive train helps increase output and decrease energy consumption. It also reduces wear and tear, thereby limiting maintenance costs and downtime while extending the life of your equipment. To attain this level of efficiency, one need only turn to the application-specific engineering found in integrated drive systems.

Read the entire white paper below, or you can download it from the Ives Equipment website here.

Labels:

Delaware,

IDS,

Maryland,

New Jersey,

New York,

Pennsylvania,

Siemens,

Siemens Integrated Drive Systems,

Virginia

HydroRanger 200 Customer Loyalty Offer from Siemens

Enhancements include faster commissioning with an improved HMI (Human Machine Interface) and graphical Quick Start Wizards as well as a redesigned enclosure with removable terminal blocks and wider communications.

The HydroRanger 200 HMI provides high performance measurement of level, flow, differential level, and volume conversion, with additional alarm and pump control functions. Siemens’ patented Sonic Intelligence signal processing technology differentiates between true and false echoes from obstructions or electrical noise, giving users repeatable, fast, and reliable measurements.

Siemens is making it easy for you to see the benefits this instrument has to offer. As a loyal customer, they are offering you a 15% discount toward the purchase of the enhanced HydroRanger(s) 200 HMI version.

Call Ives Equipment at 877-768-1600 to place your order.

Use discount code: SPR6029

(Offer valid until December 31, 2016).

Use discount code: SPR6029

(Offer valid until December 31, 2016).

Using Magmeters in Zero Upstream and Zero Downstream Applications

This video provides excellent information on installing magnetic flowmeters when you do not have optimal piping situations. The video also provides the viewer with an excellent overview of how Magmeters work.

This video provides excellent information on installing magnetic flowmeters when you do not have optimal piping situations. The video also provides the viewer with an excellent overview of how Magmeters work.The presentation reviews topics such as how Magmeter works, mounting configuration, best practices, alternatives for when required upstream/downstream piping distances are not available, the importance of a full pipe, and what kind of accuracy you can expect in less than ideal piping situations.

For more information on magnetic flowmeters visit this link or call Ives Equipment today at (877) 768-1600.

Enhance Control System Security Using Process Switches

|

| Electro-mechanical switches do not have software or an operating system susceptible to cyber attack. |

Untied Electric Controls

This white paper looks at how open Microsoft technology used in virtually all contemporary control systems, such as distributed control systems (DCS) and supervisory control and data acquisition (SCADA), can mean less security. The paper explores why current solutions may not be up to the task of protection. It also shows how simple, yet reliable electro-mechanical switch-based protection can improve cyber defenses by complementing traditional techniques with another layer of protection independent of centralized control systems.

Better Technology, Less Security

A long running trend is behind the increasing vulnerability of control systems to hacking and other forms of cyber mischief. Centralized control systems are typically tied together through an open network and software that is susceptible to cyber-attack. What’s more, the network extends out beyond the plant floor. Indeed, a part of the plant floor network is increasingly reaching around the world, thanks to web-based tools and interfaces.

Networking adds extra capabilities, information sharing, and lowers the cost of commercial off-the-shelf components used in process control systems. Data from a control system can be fed into enterprise management software, enabling the use of business intelligence techniques to tackle problems and improve overall performance.

However, current networked systems are more vulnerable to attack than yesterday’s stand-alone and analog-based setups. This increased susceptibility arises from expanding exposure on two fronts. First, an open standardized network that can be accessed around the world for good can also be manipulated globally for bad. Second, the more complex a network becomes, in terms of connected devices and topology, the more likely it is that some vulnerability will open up, particularly if system updates are not deployed in a timely manner.

Perhaps the best known and most complete example of this in a SCADA setting is the Stuxnet worm, which was discovered in June 2010. Stuxnet infects computers through infected USB ash drives and exploits multiple Microsoft Windows security vulnerabilities. More recently, another worm related to Stuxnet dubbed Duqu was discovered by a Budapest University. Built on the same source code as Stuxnet, Duqu may be one of many malware worms floating in cyberspace ready to attack.

An investigation by the Idaho National Laboratory demonstrated potential physical damage with a 27-ton power generator by sending conflicting instructions governing speed and other characteristics that induced the generator to literally shake apart, destroying it. In a simulation, Sandia National Laboratory engineers showed that turning o a recirculation pump while upping heat could incapacitate an entire oil refinery by simply destroying a critical component.

Current Solutions Need Improvement

Traditional solutions are not as effective as they once were. One aspect of the traditional approach is to patch software to plug vulnerabilities. Doing this prevents an attacker from gaining control of a system through the use of a trick - such as a buffer overflow overloading the software – thereby allowing an attacker free reign.

Yet another approach is to employ firewalls and intrusion detection devices to keep intruders out and prevent the exploitation of weaknesses. Very sensitive and critical control applications are further hardened through network segregation to limit points of contact to the outside world, making the systems more secure. Costly redundant components and controllers can also be used, if control applications are vital enough to warrant the extra expense.

In today’s world, unfortunately, all of these tactics can – and do – fail due to the efforts of smart savvy attackers. On the software side, the list of vulnerabilities in Linux, Windows, iOS, Android and other operating systems is long and growing. Despite the valiant efforts of the control system suppliers, attacks can succeed if an un-patched operating system or applications exist inside a trusted area due to lax system upgrades.

In addition, the growth of newer technologies, such as fieldbus networks, industrial wireless networks, and mobile hand-held devices is another potential path for hackers. The new crop of safety instrumented systems (SIS) shift from separated analog systems to digital networking architectures may be susceptible to operating system weaknesses. Wireless networks are new and even with the extraordinary security measures included in the standards, only one entry point out of an infinite amount due to ubiquitous access points through sensors and mobile devices is needed to create havoc.

In total, this situation means that the most secure approach possible – network segregation – is much less effective.

Turning to Tried and True Technology

Clearly, there is a need to add to the defense against cyber-attack. Ideally, the defense would operate in the event of a compromised control system. The solution has to be fast acting, as even small delays can lead to damaged equipment, toxic environmental exposure, loss of life, and long downtimes. It also has to be reliable, working when needed and not triggering at the wrong times. Finally, it has to be hack-proof and support current infrastructure.

Electro-mechanical process switches, a robust and proven technology, meet all of these requirements. At first glance, this is somewhat surprising since the technology is not typically considered for cyber security. However, electro-mechanical switches do not have software or an operating system susceptible to cyber attack. When properly applied, electro-mechanical switches can provide safety functions independent of a central control system. There is no processor involved, which means there is nothing to hack. Electro-mechanical switches are also fast, tripping quickly when milliseconds count. What’s more, modern implementations, like United Electric’s 100, 120 and 400 Series

of pressure and temperature switches, have virtually no false positives. When these switches trip, it is because a safe operating limit has been exceeded, dangerous conditions exist, or both.

The key to this approach is the placement of switches so that they monitor suitable process parameters. They also must be connected so that they can take the appropriate action. In the event of an out-of-limit process condition, the switches will trip. Since the switches can power relays, they can be wired so as to shut down compressors, pumps, turbines or whatever is needed to correct the situation and limit the damage.

Of course, the choice of what parameters to measure and where to do so will be dictated by the particular process in question. Likewise, what to have a switch act upon will also be process specific. They could, for example, shut o a compressor to keep a vessel from an overpressure situation or they could trip relays to take an entire plant floor offline.

To see the power of this approach, consider that one of the first actions taken in Sandia National Laboratory oil refinery attack simulation was to put the system on manual, thereby overriding automated safeguards. This hack attempt would have failed, though, given an appropriately placed and configured electro-mechanical switch. The switch would have tripped once the temperature exceeded a set point. There would be nothing the attacker could have done.

As an added bonus, switches protect against both deliberate and accidental catastrophes. After all, they do not care why a temperature limit, for example, has been exceeded. The situation could be due to malicious hacking or the failure of a pump circulating coolant. In either case, though, the switch would take the same action and provide an emergency shutdown.

Conclusion

As has been shown, increasing connectivity and automation have brought bene ts, such as diagnostics, predictive maintenance, and process optimization to process control. However, by bridging the gap between control systems and the world, these advances have also made automated control systems vulnerable to attack. Traditional solutions may not be adequate to safeguard systems in an environment where multiple, rapidly evolving technologies combine to create many potential weak links.

The solution involves a properly designed safety layer of electro-mechanical process switches to complement traditional software solutions. Switches are fast, reliable, hack-proof, and act independent of the control system. Electro-mechanical switches should be considered as the primary or redundant layer to protect critical equipment in today’s dangerous landscape. So, while no control system today may be an island, electro-mechanical switches can, in effect, provide protection from intruders before they can cause damage.

Labels:

cyber security,

Delaware,

Maryland,

New Jersey,

New York,

Pennsylvania,

pressure switch,

process switch,

UE,

Virginia

Wastewater Treatment Plants Save Big on Energy with Ultrasonic Controller

|

| SIEMENS LUT 400 |

For a water/wastewater treatment plant (W/WWTP), pumping is one of the most expensive parts of day-to-day operations. Varying from country to country, these costs range from 30 to 50 percent or more of a W/WWTP’s hydro bills – and in the future, this number will only increase as energy prices climb. Overall, water and wastewater treatment are one of the largest energy consumers in most municipalities, so any savings have an impact on more than just the W/WWTP.

By the Numbers

Just how much does pumping cost? Take your average 50 horsepower pump. In an hour, this pump consumes around 37 kilowatts. Do the math and at a cost of $0.065 per kilowatt hour (kWh) – Ontario, Canada’s off-peak price – that one pump costs a W/WWTP $12 every day, $4400 each year (as it has a running time of five hours per day).

But we know that many places, including Canada, the UK, Germany, South Africa, and Australia, have different rates according to the time of day or season energy is consumed. So while our single pump costs $0.065 per hour during low-energy periods, it now costs up to 80% more during Ontario’s peak-energy periods. So if the same company did all of its pumping during these peak periods, over the course of a year it would have spent an additional $3500! And remember this is just for a single pump – many W/WWTPs have hundreds of pumps, depending on a facility’s size.

Of course, no company is going to pump only in peak-energy periods – as we have just seen, that would be outrageously expensive. But, since wastewater treatment happens at all times of the day, facilities must pump during these high-cost periods.

So, How Do I Save Money?

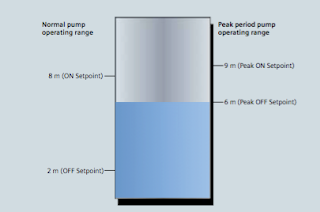

SITRANS LUT400, Siemens’ newest ultrasonic controller, features two models that control

|

| Figure 1: During peak periods, the pump operating range is much smaller than in normal operation, reducing the amount of time pumps must run. |

In normal operation, the controller will turn on pumps once water reaches the high level set point and then will begin pumping down to the low level set point. In economy pumping, the controller will pump wells down to their lowest level before the premium rate period starts, thereby maximizing the well’s storage capacity. The controller then maintains a higher level during the tariff period by using the storage capacity of the collection network. Pumping in this way ensures compliance with environmental regulations and minimizes energy use in peak tariff periods.

How Do I Set Up an Economy-pumping Regime?

Install SITRANS LUT400 ultrasonic controller and connect it to a Siemens Echomax transducer in

|

| Siemens Echomax transducers installed in the well and the SITRANS LUT400 controller measure the level of water and control pump operations. |

In the winter, these times change to 7-11 a.m. and 5-7 p.m. You can program up to ve peak zones during one 24-hour period.

To begin setting up your economy-pumping regime, enable SITRANS LUT400’s Energy Savings function. Set the Peak Lead Time to 60 minutes to start pumping water down 60 minutes before the high-cost period begins so the well is at its lowest point. Depending on the volume of your well, you can set your Peak Lead Time to any amount between zero and 65,535 minutes.

On the controller, select the Peak Start Time of 11:00 a.m. and the Peak End Time of 5:00 p.m. Set your Peak ON Setpoint to nine meters and the Peak OFF Setpoint to six meters, as shown in Figure 1.

In Normal Operation mode, the controller starts the pump when water reaches eight meters and stops the pump at two meters. In Energy Saving mode, SITRANS LUT400 turns on the pump when water reaches nine meters and stops pumping at six meters, thus running the pump for the minimum amount of time during peak tariff periods. Cost-savings through economy-pumping regimes are simple to put in place with these steps.

Don’t forget that when you are setting up your controller, you can take advantage of SITRANS LUT400’s real-time clock for daylight saving time adjustment. The real-time clock is a useful feature – input your location’s daylight saving time and economy pumping will occur throughout the year without interruption.

Infiltration and Ingress (I&I) Monitoring

|

| LUT400 controller and XRS-5 transducer in a wet well application |

Another cost-saving feature of this controller is in ltra- tion and ingress monitoring with SITRANS LUT400’s pumped volume feature and built-in datalogging capabilities.

In a closed collection network, it is inef cient and costly to pump rainwater entering the system due to leakages from degraded pipes. SITRANS LUT400 calculates pumped volumes, providing useful historical trending information for detecting abnormal increases of pumped water.

To use this feature, provide the known volume in the well between the pump’s ON and OFF setpoints. The controller will calculate the pumped volume based on the rate of level change in the well during pumping. It also calculates the in ow rate based on the rate of level change in the well just prior to pump startup.

SITRANS LUT400 logs this information for you to review via the controller’s communications options, or by connect- ing a USB cable and downloading logs directly to your computer. By comparing these results, you can see if in ow rates are greater due to rainwater entering the system. Repair those damaged pipes and the cost savings begin!

Through economy pumping and I&I monitoring, SITRANS LUT400 gives companies the potential for sig- ni cant energy savings. One SITRANS LUT400 user stated that every small change his company makes to reduce consumption has the potential to save millions of dollars each year.

For more information, contact:

Ives Equipment

(877) 768-1600

Labels:

Delaware,

LUT400,

Maryland,

New Jersey,

New York,

Pennsylvania,

pumping,

Siemens,

Virginia,

wastewater treatment

Monitoring and Control of Carbon Monoxide Emissions in a Parking Structure

|

| Parking lot CO2 Monitor (courtesy of CONSPEC) |

Reprinted with permission by CONSPEC

Carbon monoxide (CO) emissions from motor vehicles can have detrimental effects on the air quality inside subterranean parking garages. CO, an odorless, tasteless and colorless gas, is the leading cause of accidental poisoning deaths in the United States. The Centers for Disease Control estimates that CO poisoning claims nearly 500 lives and accounts for more than 15,000 visits to emergency rooms annually. When not properly ventilated, CO concentrations can build to toxic levels. Also when CO emissions fill a space, the oxygen in that space is depleted, causing asphyxiation.

Ventilation systems, therefore, are a must for today’s mixed use underground parking facilities, but they can be costly to operate 24 hours, seven days a week. This is why mechanical contractors and HVAC specialists are increasingly specifying CO monitoring and ventilations systems for both new and existing parking structures.

CARBON MONOXIDE SENSING TECHNOLOGIES

Not all CO sensors are alike. Electrochemical sensing technology provides many advantages over the older semiconductor (“solid state”) sensors or infrared sensors. Electrochemical sensors offer high resolution (≤ 0.5 ppm), a linear signal, long-term stability (≥5% over the lifetime of the sensor) and immunity to false alarms caused by “nuisance gases.”

The best CO sensing technologies will also alert facility and emergency personnel, via cell phone, in the case of dangerous concentrations of CO. Use of CO monitoring and ventilation can not only protect human health, but also can help prevent fire, as increased CO levels can sometimes predict the imminent threat of fire.

While inadequate ventilation can drastically increase the risks of liability, continuous operation of ventilation systems can

be costly. To minimize heat loss in winter, as well as conserve energy used by the ventilation fan motors, some parking garage owners began to operate ventilation systems only during peak traffic times, that is, during the morning and evening rush hours. This, however, failed to take into account instances

in which a car was left idling or parking patterns varied from the norm. This explains the growing trend toward installation of CO monitoring and ventilation control systems.

AN ALTERNATIVE TO CONTINUOUS VENTILATION

To minimize health and safety liability issues, some garage owners decided to simply run ventilation systems continuously, but this created other problems. Jeff Aiken, a project manager with Professional Mechanical Contractors, Inc., notes that continuous fan operation can mean continuous annoyance for tenants in apartments or condominiums close to fans.

“CO emissions also create tremendous liability issues,” Aiken noted, “but continuous operation is not a good solution. Installing a gas detection solves this dilemma.”

In response to the energy crisis in California in the 1980s, Conspec Controls developed a combined CO monitoring and ventilation system using electrochemical sensing technology. For maximum cost efficiency in new construction, the design should include an integrated CO monitoring and ventilation system.

The Conspec P2621 is often specified due to its large area of coverage. For instance, in a typical garage with ten-foot ceilings, one unit will cover 10,000 square feet, while competing systems require two units in the same space.

Labels:

CO2,

CONSPEC,

Delaware,

gas detection,

Maryland,

New Jersey,

New York,

parking lot,

Pennsylvania,

Virginia

Examining the User Interface of the SensAlert ASI Gas Detector

The Sensidyne SensAlert ASI provides enhanced protection and dependability for critical safety applications where personnel, processes, and facilities are at risk. The third party certified SIL-2 SensAlert ASI offers dependability and versatility while remaining the easiest to install, commission, operate, and maintain.

The video below demonstrates the setting menu and the operator interface.

The product is third-party certified to IEC61508 Level 2 (SIL-2) for both hardware and software with certification to global hazardous area and performance standards. The Test-on-Demand feature with on-board gas generator provides remote functionality checks with generated gas while Predictive Sensor End-of-Life Indication provides advanced warning of impending sensor failure.

SensAlert ASI is a universal instrument platform for toxic & combustible gas detection and oxygen monitoring. Intrinsically safe or explosion proof installation configurations with options for remote sensors and gassing, duct mount, and sample-draw maximize application versatility. Intrinsically safe or explosion proof installation configurations for remote sensors and gassing, duct mount, and sample-draw maximize application versatility. The sensor head accepts all Plus Series sensor technologies – infrared, catalytic bead, and electro-chemical. Assignable and configurable relays together with communication options provide broad flexibility. The SensAlert ASI I.S. sensor head can be remote mounted up to 100 feet (30m) from the transmitter providing a useful option to position the transmitter in a personnel-accessible location while positioning the sensor closer to potential hazards.

The product is third-party certified to IEC61508 Level 2 (SIL-2) for both hardware and software with certification to global hazardous area and performance standards. The Test-on-Demand feature with on-board gas generator provides remote functionality checks with generated gas while Predictive Sensor End-of-Life Indication provides advanced warning of impending sensor failure.

SensAlert ASI is a universal instrument platform for toxic & combustible gas detection and oxygen monitoring. Intrinsically safe or explosion proof installation configurations with options for remote sensors and gassing, duct mount, and sample-draw maximize application versatility. Intrinsically safe or explosion proof installation configurations for remote sensors and gassing, duct mount, and sample-draw maximize application versatility. The sensor head accepts all Plus Series sensor technologies – infrared, catalytic bead, and electro-chemical. Assignable and configurable relays together with communication options provide broad flexibility. The SensAlert ASI I.S. sensor head can be remote mounted up to 100 feet (30m) from the transmitter providing a useful option to position the transmitter in a personnel-accessible location while positioning the sensor closer to potential hazards.

Labels:

Delaware,

Eastern Pennsylvania,

gas detection,

Maryland,

New Jersey,

New York,

safety,

SensAlert,

Sensidyne,

SIL,

Virginia,

West Virginia

Food Processing: Belt Scales Improve Tomato Processor Efficiency and Productivity

|

| Belt Scales Improve Tomato Processing |

Application:

A tomato processor located on the Pacific coast uses the latest technologies in peeling, dicing, and packaging tomatoes. They were preparing to replace some of their older weigh feeders because of declining performance. One of their main concerns with installing new weigh feeders was the cost of moving the existing conveying systems in order to accommodate new weigh feeders.

See the document below for the full case history:

Labels:

belt scale,

Delaware,

Eastern Pennsylvania,

Maryland,

New Jersey,

New York,

Siemens,

Virginia,

weigh feeder,

weighing,

West Virginia

2 Wire, 3 Wire, and 4 Wire RTD Sensor Connections

|

| Industrial temperature transmitters (courtesy of Siemens) |

Industrial temperature transmitters are devices that measure the temperature of a process and provide a measurable output over some desired temperature range. Industrial temperature transmitters primarily use either of two popular temperature sensors - the thermocouple or the RTD (resistance temperature detector). The RTD changes resistance as process temperature changes, while a thermocouple provides a changing micro-voltage with process temperature change. RTDs are inherently more accurate, but require excitation voltage. There are three style RTD's - 2-wire, 3-wire, and 4-wire.

|

| Proper wiring of RTDs |

It is critically important to note that the common connections shown by the symbols for 3- and 4-wire RTD sensors represent junction points at the sensor; not terminals jumpered by the technician at the time of installation, and not internal jumpers inside the transmitter. The whole purpose of having 3-wire and 4-wire RTD circuits is to eliminate errors due to voltage drop along the current-carrying wires, and this can only be realized if the “sensing” wire(s) extend out to the RTD itself and connect there. If the transmitter’s sensing terminal(s) are only jumpered to a current- carrying terminal, the transmitter will sense voltage dropped by the RTD plus voltage dropped by the current-carrying wire(s), leading to falsely high temperature indications.

Click here for more information on industrial RTDs and temperature transmitters.

For more information about any temperature measuring application, contact:

Ives Equipment

www.ivesequipment.com

(877) 768-1600

For more information about any temperature measuring application, contact:

Ives Equipment

www.ivesequipment.com

(877) 768-1600

Some of above content taken from Lessons In Industrial Instrumentation by Tony R. Kuphaldt – under the terms and conditions of the Creative Commons Attribution 4.0 International Public License.

Combustion Analyzer Adds Higher Level of Safety by Measuring O2, Combustibles, and Methane

The reliable identification of low combustion oxygen in a fired

heater or boiler has always been critical to the effectiveness of the

Burner Management System for proper control and safety.

The reliable identification of low combustion oxygen in a fired

heater or boiler has always been critical to the effectiveness of the

Burner Management System for proper control and safety.Low emission burners and aggressive firing control points to achieve increased efficiency and emission reductions have driven the industry to tighter control measures. But tighter control measures also hold a greater potential for combustion events. Reducing the risk of a combustion event has become a priority and has led to the implementation of Safety Instrumented Systems (SIS). This additional layer of safety is added to the Basic Process Control System.

The WDG-V has been designed to provide an additional layer of safety with the measurement of excess O2, Combustibles and Methane and by using these measurements to ensure the safe operation of the Burner Management System.

Lost Plant Air a Hidden Source for Energy Savings

|

| Save energy costs by reducing consumption of plant air. |

Plant maintenance are becoming more aware of air leaks and the subsequent increases in cost to overcome lost power because of those leaks. One of the major culprits for lost air in a plant is the pneumatic control valve positioner and the air required to operate them. In a typical process plant, there could be hundreds of control valves. Each control valve uses a positioner to move the valve actuator, based on a set point signal from a controller.

|

| Control valve with Siemens SIPART |

Years ago, when electricity was cheap and when valve positioners were first introduced, plant maintenance and engineering were not concerned with something called the “bleed rate” of the positioner. Over the years though, plant personnel lost track of bleed rate and pretty much forgot that a positioner is just part of the system and it operates on air. Today, a modern process facility such as a power plant, refinery, or chemical plant can have several hundred control valves with positioners. The combined air loss due to the positioner “bleed rate” can be significant.

|

| Siemens SIPART positioners |

The significant change in technology came with the adoption of the adoption of a piezo ceramic valve block in low bleed positioners. Traditional positioners used an I/P and spool valve which both leaked air. Over time the leaks from these two parts is significant.

Could you and your plant be in the situation where lost energy efficiency through leaky positioners is costing big bucks? If you’re even the slightest bit concerned, call in an applications expert now for a system review.

Labels:

Delaware,

Eastern Pennsylvania,

energy,

Maryland,

New Jersey,

positioner,

Siemens,

SIPART,

valve,

Virginia,

West Virginia

Subscribe to:

Posts (Atom)