|

| Low-Flow Measurement in Supercritical Fluid Extraction |

A food producer removes caffeine from coffee beans to create a decaffeinated version of its most popular blend. A manufacturer of dietary supplements extracts pesticides and organic solvents from ginseng to ensure a higher-quality end product. A crime laboratory measures the amount of morphine in a blood sample to analyze the usage habits of a drug addict.

These scenarios might not appear to share much in common – after all, what does your favorite morning beverage have to do with forensic drug testing? – but there are important similarities. In each example, a supercritical fluid can be used to carry out precise, efficient, low-toxicity chemical extraction or chromatography.

|

SITRANS F C MASS 2100

sensor paired with the

SITRANS FCT010

digital transmitter |

Regardless of the industry or application, supercritical fluid extraction (SFE) and super- critical fluid chromatography (SFC) require a very specific set of operating conditions. Keeping the environment just right for SFE and SFC requires consistently accurate process measurements – all of which are made possible by incorporating a high-performance Coriolis mass flowmeter designed to measure accurately at low flow rates.

Download this Application Note Here

The Application

An analytical science corporation in the northeastern USA develops instruments for laboratory-based applications across a broad range of industrial, academic and government organizations. Among their specialties are SFE and SFC systems tailored to the specific needs of customers and designed to extract and/or measure a variety of chemical compounds.

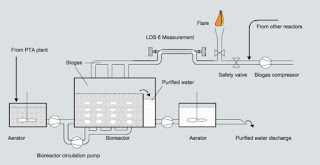

Their systems rely on supercritical carbon dioxide (CO2) instead of organic solvents to provide selective sample extractions and/or measurement. CO2 normally behaves as a gas at standard temperature and pressure, or as dry ice when frozen. But when CO2 is held at or above its critical temperature of 31.2 °C (87.8 °F) and critical pressure of 73.8 bar (1071.6 psi), it achieves a super- critical state midway between a gas and a liquid, with liquid-like density and solvating power but a viscosity near zero. Using supercritical CO2 results in shorter completion times and purer extracts – not to mention lower operating costs in comparison to solvent-based systems.

To kick off SFE or SFC, supercritical CO2 is pumped into the system and passes through an integrated Coriolis flowmeter, which measures the incoming mass flow rate, density and temperature. This is a crucial step in both processes, as it’s the prima- ry way to ensure that all CO2 flowing into the system remains in the desired fluid state. Once conditions are verified by the flowmeter, the CO2 helps to extract the compounds (in SFE) or separate and measure them (in SFC).

The Challenge

For more than 15 years, the company has had the option to add a SITRANS F C Coriolis flowmeter from

Siemens to their SFE and SFC systems, depending on customer requirements. Their meter of choice consisted of a MASS 2100 sensor in size DI 1.5 (1/16”) and a MASS 6000 transmitter. They initially selected the Siemens solution because of its capability for very accurate measurement – as high as 0.1% of flow rate – under the low-flow conditions required for chemical extraction and measurement with supercritical CO2. The robust construction of the MASS 2100 sensor also offered the reassurance of long-term durability, even in high-pressure environments.

Over time, the company recognized the need to expand into a broader market- place by ensuring that all of their super- critical fluid solutions complied with the RoHS Directive for hazardous materials, which would open the opportunity to sell into the European Union. Having come to appreciate the reliability of the SITRANS F C product line and the responsiveness of Siemens customer support, they turned to Siemens for a digitally based, RoHS-compliant Coriolis flow alternative. That’s when they were introduced to the SITRANS FCT010.

The Solution

Part of the next-generation digital flow platform from Siemens, the FCT010 is a powerful, very compact Coriolis transmitter designed especially for skids and other small-footprint assemblies – a major benefit for the SFE and SFC systems given their limited availability of space.

Another prerequisite for selection was superior performance, and the FCT010 does not disappoint. The transmitter measures with advanced digital signal processing technology, so it produces a stronger signal-to-noise ratio than an analog transmitter for higher accuracy, improved resistance to process noise and a more stable zero point. The FCT010 can also detect and respond to even the smallest changes in flow with a best-in-class 100 Hz update rate.

The company was pleased to learn that the new transmitter could be paired seamlessly with the existing MASS 2100 sensor, which over the course of 15 years has proven to be the ideal low-flow sensor for measuring supercritical CO2. They also liked that the FCT010 is extremely simple to install as a result of its small size and easy-to-use wiring connections.

Ultimately, they placed an order for 100 FCT010 transmitters to be included with new SFE and SFC systems. Now that the enhanced Coriolis flow solutions are in place, the upgraded systems are benefit- ting from faster communication coupled with better process data – all of which adds up to higher-precision, more effi- cient extractions and measurements for laboratories.

With help from the digitally powered SITRANS F C Coriolis flow family, the corporation is equipping manufacturers and researchers with advanced tools that optimize science, commerce and their bottom lines.

For more information,

call Ives Equipment at (877) 768-1600 or visit

https://ivesequipment.com.

Reprinted with permission from Siemens.