|

| One Series Pressure and Temperature Transmitter-Switches (United Electric) |

With more than 80 years of evolution since its introduction, switch technology as changed significantly enough that some of the common beliefs about switches are no longer true. Seven common myths surrounding switches are analyzed. Recent technology advancements in switch design and how these advancements solve problems in industrial and OEM applications are discussed. Readers will acquire a better understanding of the new technology available to improve control, process efficiency and safety.

1. Blind & Dumb

Prior generations of switches were incapable of displaying process measurements locally, forcing the installation of gauges that created more leak paths and added additional costs. Operators were unaware when installed switches stopped functioning due to welded contacts in the microswitch. Switches required removal from service and manual testing to conform functionality. Often, the control or safety function would go unprotected for days while the switch was in queue to be bench tested, creating an immediate safety concern.

These industry-wide problems inspired manufactures to innovate the next generation of switches that incorporate liquid crystal displays (LCD), presenting local process variable measurements, and integrated internal diagnostics, monitoring the health of the device. The addition of LCDs and device diagnostics increases up me and improves overall plant safety. Original equipment manufacturers (OEM) benefit from a reduction in installed components and a more dependable turnkey product for their customers.

2. Difficult Adjustments

Set point and deadband adjustments were a nuisance for operators and technicians. The instruments were required to be removed from service and calibrated on a bench in the maintenance shop. Installation instructions were not always available for installed devices, leading to wasted me searching for documentation or requesting additional information from the manufacturer. Delicate adjustments were required to achieve desired set points and deadbands, the dead time where no action happens, varied based on the microswitch inside the control. More often than not, instruments were mis- handled leading to premature failure due to inexperienced technicians.

Today’s generation of switches offer electronic platforms that reduce setup and programming to a ma er of seconds. A user interface on the local LCD provides simple prompts that allow users to program switch set points instantly without the need to remove the instrument from the process. Deadband and set point are now 100 percent adjustable, allowing operators to choose the desired range based on the application requirements. No longer are operators required to order and stock redundant devices in the event one failed in the eld. Users now have the flexibility of programming one switch to match many different process requirements.

3. Unsafe in Critical Applications - Not Appropriate for SIS

Industrial process plants are pushing pressure and temperature limits to new boundaries in an effort to stay competitive in a global market. Many of the systems designed 20 years ago were not intended to run at the current process extremes. It is only a ma er of me before these systems fail. Safety instrumented systems (SIS) are being installed to protect the process, people and the environment. These systems require devices that have been rigorously tested by third party agencies to verify the level of safety performance. Mechanical switches, referred to as sensors in SIS, are one of the most common components to fail in these systems. Users and designers require a switch that matches their required system performance level while also being fault tolerant.

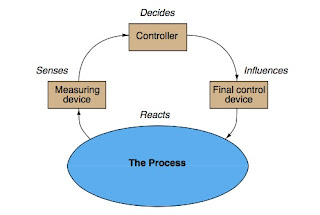

Based on the strict performance requirements of SIS, newly introduced hybrid switches integrate the functionality of a switch and a transmitter. The switch portion of the device provides a direct digital output (relay output) to a final element that will instantly bring a process to a safe state in the event of a critically abnormal situation. The analog transmitter signal can be used for trending to determine the health of the device and the process. These new transmitter-switches and recently SIL 2 and 3 exida-certified devices (One Series Safety Transmitter) offer operators a simple and safe product that matches the demanding performance requirements of safety instrumented systems.

4. Problematic in Tough Environments

Whether installed on plant rotating equipment, such as turbines, or on demanding OEM auxiliary equipment, such as pumps or compressors, switches are required to function in tough environments that include shock, vibration, heat and pressure. Vibration is one of the leading causes of electro- mechanical switch failure. Most switches are mechanical in design and utilize a plunger to activate a microswitch. In areas of high shock and vibration, the plunger position can fluctuate and lead to false trips.

New solid-state, electronic switches provide a solution to the common problems with mechanical switches installed in high vibration applications. Because they have no moving parts, these switches can be mounted directly to the equipment or process without connecting impulse lines to keep them isolated from vibration. Industry leading turbine manufacturers and end users operating large compressors in petrochemical plants are experiencing much more reliability and fewer false trips with these new electronic switches, compared to the old mechanical designs.

5. Deploy Electromechanical Designs When Line Power is Unavailable

Most pressure switches sold over the past 80 years were designed to operate without electric power by incorpora ng a sensor that measures pressure by placing force on a plunger that would actuate a microswitch.

The first genera on of digital switches required line power to operate and were not adopted due the unavailability of line power and the cost of wiring. The new genera on of switches operates from leakage current in the circuit when connected to a host device, such as a Programmable Logic Controller (PLC), allowing electronic switches to be drop-in replacements for the old mechanical switches. Today, we have the ability to replace a blind and dumb mechanical switch with a new solid-state, electronic switch that offers a digital gauge, switch and transmitter in one instrument without adding any wiring or hardware.

6. Antiquated Technology

Today’s process plants run their processes faster and ho er than they were originally designed. Ultimately, these plants will have to ini ate modernization projects to support the new demands of the process. Old switches provided users with digital, on-off signals that were either wired to control a piece of equipment directly or sent to a PLC for alarm functionality. As plants go through modernization projects, they restructure control system input/outputs (I/O) to support more analog signals than the digital signals used in the past. Transmitters are commonly chosen and recommended over switches in these new projects, but transmitters do not provide the internal control functionality found in switches.

These modernization projects are costly requiring new equipment, updated wiring, expanded I/O, extensive engineering resources, and costly down me. Users are diligently exploring new ways to reduce overall project costs. The average process transmitter can cost upwards of $2,000 compared to the average process switch costing around $500. Process plants often have 100 to 1,000 switches installed. To upgrade all switches to transmitters could cost a plant up to $1.5 million. Consequently, switch manufacturers researched and developed new electronic switches that are capable of producing both digital and analog signals required by these new modernization projects, while keeping a similar price point to the original mechanical switches installed.

This dramatic savings allows plants to reduce the overall modernization project costs by upgrading the 2nd most likely component (sensor) to fail in a tradional safety system, without upgrading the rest of the safety system and reducing the down me needed to complete the project during a short shut- down turn- around project.

7. The Speed of Response of Transmitters is Faster than Switches

Without question, electromechanical switches are faster than any pressure transmitter on the market. With transmitters, huge amounts of conversions, computations, compensation, and other work must be done to get an accurate signal. Even using today’s high-speed processors, they cannot match the speed of the instantaneous reaction of a mechanical device. The fastest of these devices can be be er than 5 milliseconds while process transmitters can range from 300-500 milliseconds or more. Purpose built transmitters for safety applications designed for speed of response in lieu of accuracy (not needed in safety applications) can be as fast as 250 milliseconds. New solid state transmitter-switches can react in 100 milliseconds or less in the switch mode. If your application requires fast response such as in positive displacement (PD) pumps and turbine trip for over-speed protection, consider new solid-state transmitter-switches over process transmitters.

Recommendations

United Electric Controls has recognized the challenges faced by users and developed new products to match their growing needs. In an effort to reduce plant project costs and help OEMs design and build affordable and reliable equipment for the industrial sector, we have developed a new line of electronic switches that provide drop-in replacement of old mechanical switches. These new switches reduce the costs of plant modernizations. Built-in digital and analog communication provides users the op on of control- ling a piece of equipment locally or sending information back to a central control system for process trending and health, or both.

Prior generations of switches were incapable of displaying process measurements locally, forcing the installation of gauges that created more leak paths and added additional costs. Operators were unaware when installed switches stopped functioning due to welded contacts in the microswitch. Switches required removal from service and manual testing to conform functionality. Often, the control or safety function would go unprotected for days while the switch was in queue to be bench tested, creating an immediate safety concern.

These industry-wide problems inspired manufactures to innovate the next generation of switches that incorporate liquid crystal displays (LCD), presenting local process variable measurements, and integrated internal diagnostics, monitoring the health of the device. The addition of LCDs and device diagnostics increases up me and improves overall plant safety. Original equipment manufacturers (OEM) benefit from a reduction in installed components and a more dependable turnkey product for their customers.

2. Difficult Adjustments

Set point and deadband adjustments were a nuisance for operators and technicians. The instruments were required to be removed from service and calibrated on a bench in the maintenance shop. Installation instructions were not always available for installed devices, leading to wasted me searching for documentation or requesting additional information from the manufacturer. Delicate adjustments were required to achieve desired set points and deadbands, the dead time where no action happens, varied based on the microswitch inside the control. More often than not, instruments were mis- handled leading to premature failure due to inexperienced technicians.

Today’s generation of switches offer electronic platforms that reduce setup and programming to a ma er of seconds. A user interface on the local LCD provides simple prompts that allow users to program switch set points instantly without the need to remove the instrument from the process. Deadband and set point are now 100 percent adjustable, allowing operators to choose the desired range based on the application requirements. No longer are operators required to order and stock redundant devices in the event one failed in the eld. Users now have the flexibility of programming one switch to match many different process requirements.

3. Unsafe in Critical Applications - Not Appropriate for SIS

Industrial process plants are pushing pressure and temperature limits to new boundaries in an effort to stay competitive in a global market. Many of the systems designed 20 years ago were not intended to run at the current process extremes. It is only a ma er of me before these systems fail. Safety instrumented systems (SIS) are being installed to protect the process, people and the environment. These systems require devices that have been rigorously tested by third party agencies to verify the level of safety performance. Mechanical switches, referred to as sensors in SIS, are one of the most common components to fail in these systems. Users and designers require a switch that matches their required system performance level while also being fault tolerant.

Based on the strict performance requirements of SIS, newly introduced hybrid switches integrate the functionality of a switch and a transmitter. The switch portion of the device provides a direct digital output (relay output) to a final element that will instantly bring a process to a safe state in the event of a critically abnormal situation. The analog transmitter signal can be used for trending to determine the health of the device and the process. These new transmitter-switches and recently SIL 2 and 3 exida-certified devices (One Series Safety Transmitter) offer operators a simple and safe product that matches the demanding performance requirements of safety instrumented systems.

4. Problematic in Tough Environments

Whether installed on plant rotating equipment, such as turbines, or on demanding OEM auxiliary equipment, such as pumps or compressors, switches are required to function in tough environments that include shock, vibration, heat and pressure. Vibration is one of the leading causes of electro- mechanical switch failure. Most switches are mechanical in design and utilize a plunger to activate a microswitch. In areas of high shock and vibration, the plunger position can fluctuate and lead to false trips.

New solid-state, electronic switches provide a solution to the common problems with mechanical switches installed in high vibration applications. Because they have no moving parts, these switches can be mounted directly to the equipment or process without connecting impulse lines to keep them isolated from vibration. Industry leading turbine manufacturers and end users operating large compressors in petrochemical plants are experiencing much more reliability and fewer false trips with these new electronic switches, compared to the old mechanical designs.

5. Deploy Electromechanical Designs When Line Power is Unavailable

Most pressure switches sold over the past 80 years were designed to operate without electric power by incorpora ng a sensor that measures pressure by placing force on a plunger that would actuate a microswitch.

The first genera on of digital switches required line power to operate and were not adopted due the unavailability of line power and the cost of wiring. The new genera on of switches operates from leakage current in the circuit when connected to a host device, such as a Programmable Logic Controller (PLC), allowing electronic switches to be drop-in replacements for the old mechanical switches. Today, we have the ability to replace a blind and dumb mechanical switch with a new solid-state, electronic switch that offers a digital gauge, switch and transmitter in one instrument without adding any wiring or hardware.

6. Antiquated Technology

Today’s process plants run their processes faster and ho er than they were originally designed. Ultimately, these plants will have to ini ate modernization projects to support the new demands of the process. Old switches provided users with digital, on-off signals that were either wired to control a piece of equipment directly or sent to a PLC for alarm functionality. As plants go through modernization projects, they restructure control system input/outputs (I/O) to support more analog signals than the digital signals used in the past. Transmitters are commonly chosen and recommended over switches in these new projects, but transmitters do not provide the internal control functionality found in switches.

These modernization projects are costly requiring new equipment, updated wiring, expanded I/O, extensive engineering resources, and costly down me. Users are diligently exploring new ways to reduce overall project costs. The average process transmitter can cost upwards of $2,000 compared to the average process switch costing around $500. Process plants often have 100 to 1,000 switches installed. To upgrade all switches to transmitters could cost a plant up to $1.5 million. Consequently, switch manufacturers researched and developed new electronic switches that are capable of producing both digital and analog signals required by these new modernization projects, while keeping a similar price point to the original mechanical switches installed.

This dramatic savings allows plants to reduce the overall modernization project costs by upgrading the 2nd most likely component (sensor) to fail in a tradional safety system, without upgrading the rest of the safety system and reducing the down me needed to complete the project during a short shut- down turn- around project.

7. The Speed of Response of Transmitters is Faster than Switches

Without question, electromechanical switches are faster than any pressure transmitter on the market. With transmitters, huge amounts of conversions, computations, compensation, and other work must be done to get an accurate signal. Even using today’s high-speed processors, they cannot match the speed of the instantaneous reaction of a mechanical device. The fastest of these devices can be be er than 5 milliseconds while process transmitters can range from 300-500 milliseconds or more. Purpose built transmitters for safety applications designed for speed of response in lieu of accuracy (not needed in safety applications) can be as fast as 250 milliseconds. New solid state transmitter-switches can react in 100 milliseconds or less in the switch mode. If your application requires fast response such as in positive displacement (PD) pumps and turbine trip for over-speed protection, consider new solid-state transmitter-switches over process transmitters.

Recommendations

United Electric Controls has recognized the challenges faced by users and developed new products to match their growing needs. In an effort to reduce plant project costs and help OEMs design and build affordable and reliable equipment for the industrial sector, we have developed a new line of electronic switches that provide drop-in replacement of old mechanical switches. These new switches reduce the costs of plant modernizations. Built-in digital and analog communication provides users the op on of control- ling a piece of equipment locally or sending information back to a central control system for process trending and health, or both.

About this white paper:

UE ViewPoint white papers provide Executive, Business and Technical Briefs written by product, application and industry subject matter experts employed by United Electric Controls. For more UE ViewPoint papers, visit this link.