|

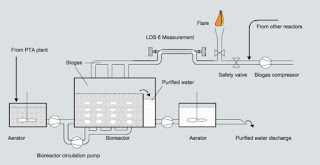

| Waste water treatment and location of the measurement. |

Purification of Process Waste Water

In the waste water treatment plant, the water treatment starts with aeration. The last step is an anaerobic bio reactor where the treatment is done in a controlled atmosphere. Micro organisms purify the water and produce biogas. Biogas roughly consists of 60 % methane and 40 % Carbon dioxide. This biogas is compressed and used as a fuel to reduce the net energy supply.

Although production or intrusion of oxygen into the reactors or pipes is highly unlikely, safety systems are installed. In case air enters unexpectedly into the process this first may result in a non-supporting atmosphere for the microbes and in the worst case the gas mixture may lead to an explosion.

Safety Guaranteed Using Siemens LDS 6

To ensure that oxygen never exceeds the maximum accepted concentration, the customer chose an in-situ measurement with the Siemens Laser Diode Spectrometer LDS 6. LDS 6 performs a continuous monitoring of the oxygen concentration in the biogas produced.

Although production or intrusion of oxygen into the reactors or pipes is highly unlikely, safety systems are installed. In case air enters unexpectedly into the process this first may result in a non-supporting atmosphere for the microbes and in the worst case the gas mixture may lead to an explosion.

Safety Guaranteed Using Siemens LDS 6

To ensure that oxygen never exceeds the maximum accepted concentration, the customer chose an in-situ measurement with the Siemens Laser Diode Spectrometer LDS 6. LDS 6 performs a continuous monitoring of the oxygen concentration in the biogas produced.

|

| Measurement path and the two LDS 6 sensor heads. |

The response of the system is in three levels:

- In case the oxygen level exceeds 5 % an alarm is triggered.

- The threshold of 7 % causes an automatic nitrogen injection and the closure of a valve preventing the gas mixture from entering into the compressor.

- When the limit of 9 % is exceeded, this automatically shuts down the compressor.

The in-situ measurement leads to a fast and reliable measurement.

The stability and availability of the LDS 6 system is ensured by the integrated reference cell which provides a lifetime calibration. To be absolutely on the safe side, the customer operates a weekly safety check which involves opening a valve that allows a controlled air intake into the LDS 6 sensor heads. As the sensor heads are physically separated from the process by process windows, no oxygen may enter into the process. The reaction of the system shows in any of these tests once more the reliability of the measurement method used.

For more information about this application, or for any analytical instrument requirement, contact Ives Equipment by calling (877) 768-1600 or visiting https://www.ivesequipment.com.

Reprinted with permission from Siemens Case Study.

Reprinted with permission from Siemens Case Study.