The latest catalog for Flowserve Worcester Control industrial ball valves, pneumatic actuators and electric actuators, courtesy of Ives Equipment. Worcester was founded in 1955. It supplies valves throughout the world for virtually any application. These include standard flanged ball valves, ANSI and DIN specifications in reduced and full bore, three-piece valves for cryogenic, high pressure, steam, diverter or sampling duty, high integrity valves, multi-way designs, modulating controls or customized solutions.

Download a PDF version of the "Worcester Controls Industrial Valve and Actuator Catalog" here or review in the embedded document below.

Educational information on process control, industrial instrumentation, valves, valve automation and control valves. For additional information visit IvesEquipment.com or call 877-768-1600

Positive Displacement Flowmeters

|

| Oval Gear Flowmeter (Macnaught) |

- Oscillating piston

- Oval Gear

- Nutating disk

- Rotary vane

- Diaphragm

|

| Oscillating Piston Flowmeter (Niagara Meter) |

Positive displacement flowmeters can be applied to liquid or gaseous media, with the selection of the mechanical internals being a significant factor in the suitability of a design for a particular application. The longstanding use of positive displacement flowmeters across various industries has been a source of stability in terms of design, with the most recent advancements in positive displacement technology focusing on maintaining precision at lower costs.

|

| Nutating Disc Flowmeter (Niagara Meter) |

There are a few known limitations for the use of positive displacement meters. The meters are not the optimal choice for measuring fluids with large particles, and are also non-ideal for measuring fluids with large air pockets. Additionally, systems using positive displacement meters need to account for slight pressure drops in the positive displacement meter.

Share all of your flow measurement requirements and challenges with process instrumentation experts, combining your own process knowledge and experience with their product application expertise to develop effective solutions.

Understanding Valve Positioners

|

| Valve positioner on linear control valve (Siemens SIPART) |

A valve positioner is used in tandem with a valve actuator, the power source to open or close the valve. Positioners precisely direct the actuator to move the valve so that a desired flow volume is achieved and maintained. The positioner does this by monitoring the process condition, comparing it to a desired set point, and then pneumatically, electrically, or hydraulically manipulating the valve orifice until the difference between the set point and actual process variable is zero.

In closed loop control systems where the final control element are valves, valve positioners are the "brains" that provide the corrective signal to eliminate process offset. Positioners enable tighter control by overcoming the realities of valve wear, imprecise calibration, and a host of other process variable challenges.

Valve positioners are used throughout the process industries including power, pharmaceutical, chemicals, oil and gas, food and beverage, pulp and paper, refining and petrochemicals, pipelines, and many other processes.

Basic Function

|

| Diagram of typical flow control loop using valve positioner. |

Types of valve positioners:

Pneumatic Positioners

Pneumatic positioners receive pneumatic signals (3-15 or 6-30 PSIG) and proportion the supply air pressure to the valve actuator accordingly to move the valve to the required position. Pneumatic positioners are intrinsically safe and have the ability to provide a large amount of force to open or close a valve.Electro-Pneumatic Positioners

Electro-pneumatic valve positioners are very similar to pneumatic postioners, except that they contain internal current-to-pneumatic converter (I/P). The current-to-pneumatic module receives a varying electrical signal (most commonly 4-20 mA) and converts that signal (proportionately) to a pneumatic output signal (3-15 PSIG or 6-30 PSIG). The pneumatic signal then then proportions the supply air pressure to the valve actuator.Electric Positioners

Electric valve positioners receive an electric signal, usually 4-20 mA, 1-5 VDC, 2-10 VCD or 0-10 VDC and generally drive the motors in electric actuators. They perform the same function as pneumatic positioners do, but use electricity instead of air pressure as an input signal.For more information on valve positioners, or any valve automation requirement, contact Ives Equipment by visiting https://ivesequipment.com or calling 877-768-1600.

Labels:

Delaware,

Maryland,

New Jersey,

New York,

Pennsylvania,

positioner,

Siemens,

SIPART,

valve automation,

Virginia

Tutorial: How to Use the Push Buttons on the SIEMENS SITRANS P Family of Transmitters

The SIEMENS SITRANS P stands above the competition when it comes to easy operation. This video provides an outstanding tutorial on how the SITRANS P push buttons and display are used.

SITRANS P offer a complete family of devices that include digital pressure transmitters for measuring gauge pressure, absolute pressure, differential pressure, flow and level.

https://ivesequipment.com

(877) 768-1600

SITRANS P offer a complete family of devices that include digital pressure transmitters for measuring gauge pressure, absolute pressure, differential pressure, flow and level.

https://ivesequipment.com

(877) 768-1600

Labels:

Delaware,

Maryland,

New Jersey,

New York,

Pennsylvania,

Siemens,

Sitrans P,

transmitter,

tutorial,

Virginia

Excellent Reference for Engineers: Table of Gases

|

| Handy Table of Gases courtesy of Control Instruments |

The table can be found here: http://www.controlinstruments.com/table-of-gases

Control Instrument Corporation manufacturers gas detection instruments for safety and environmental protection. Control Instruments products are installed and used under the most demanding conditions, from oil pipelines in the Arctic to drilling wells in the desert.

Control Instrument Corporation manufacturers gas detection instruments for safety and environmental protection. Control Instruments products are installed and used under the most demanding conditions, from oil pipelines in the Arctic to drilling wells in the desert.

For more information on Control Instruments products, contact Ives Equipment by visiting https://ivesequipment.com, or by calling (877) 768-1600.

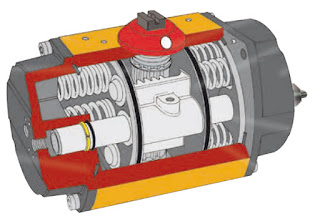

What Are Rack and Pinion Actuators?

|

| Operation rack and pinion actuator. |

There are three primary kinds of valve actuators are commonly used: pneumatic, hydraulic, and electric.

Pneumatic actuators can be further categorized as scotch yoke design, vane design, and the subject of this post - rack and pinion actuators.

How Rack and Pion Actuators Operate

|

| Image courtesy of Wikipedia |

Pneumatic actuators use pistons that are attached to the rack. As air or spring power is applied the to pistons, the rack changes position. This linear movement is transferred to the rotary pinion gear (in both directions) providing bi-directional rotation to open and close the connected valve.

Rack and pinion actuators pistons can be pressurized with air, gas, or oil to provide the linear the movement that drives the pinion gear. To rotate the pinion gear in the opposite direction, the air, gas, or oil must be redirected to the other side of the pistons, or use coil springs as the energy source for rotation. Rack and pinion actuators using springs are referred to as "spring-return actuators". Actuators that rely on opposite side pressurization of the rack are referred to as "direct acting".

|

| Internal view of rack and pinion actuator |

NAMUR mounting dimensions on actuator pneumatic port connections and on actuator accessory holes and drive shaft are also common design features to make adding pilot valves and accessories more convenient.

|

| Rack and pinion actuator with valve. (Flowserve Worcester) |

Share your process valve control and automation challenges with application experts, and combine your process experience and knowledge with their product application expertise to develop effective solutions.

Labels:

Delaware,

Flowserve,

Maryland,

New Jersey,

New York,

Pennsylvania,

rack and pinion,

valve actuation,

Virginia,

Worcester

Subscribe to:

Comments (Atom)