|

| Operation rack and pinion actuator. |

There are three primary kinds of valve actuators are commonly used: pneumatic, hydraulic, and electric.

Pneumatic actuators can be further categorized as scotch yoke design, vane design, and the subject of this post - rack and pinion actuators.

How Rack and Pion Actuators Operate

|

| Image courtesy of Wikipedia |

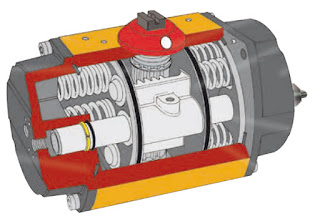

Pneumatic actuators use pistons that are attached to the rack. As air or spring power is applied the to pistons, the rack changes position. This linear movement is transferred to the rotary pinion gear (in both directions) providing bi-directional rotation to open and close the connected valve.

Rack and pinion actuators pistons can be pressurized with air, gas, or oil to provide the linear the movement that drives the pinion gear. To rotate the pinion gear in the opposite direction, the air, gas, or oil must be redirected to the other side of the pistons, or use coil springs as the energy source for rotation. Rack and pinion actuators using springs are referred to as "spring-return actuators". Actuators that rely on opposite side pressurization of the rack are referred to as "direct acting".

|

| Internal view of rack and pinion actuator |

NAMUR mounting dimensions on actuator pneumatic port connections and on actuator accessory holes and drive shaft are also common design features to make adding pilot valves and accessories more convenient.

|

| Rack and pinion actuator with valve. (Flowserve Worcester) |

Share your process valve control and automation challenges with application experts, and combine your process experience and knowledge with their product application expertise to develop effective solutions.