https://ivesequipment.com

Educational information on process control, industrial instrumentation, valves, valve automation and control valves. For additional information visit IvesEquipment.com or call 877-768-1600

Preventing Winter Shutdowns: How Freeze Protection Ensures Continuous Industrial Operations

https://ivesequipment.com

Nelson Heat Trace Design Suite by Emerson: Online Software Used to Develop Bills of Materials and Detailed Design Documents

Protect Your Process Equipment and Your Production Uptime with Heat Tracing Products from Ives Equipment

Allow us to be your trusted and dependable source for staying operating during the severe winter months, based on our decades of experience in industrial and commercial freeze protection.

As winter weather begins to set in, it is critical to take precautionary measures to preserve essential equipment. Because of the lower temperatures and strong winds, outdoor gear is at risk of freezing, which can cause the production process to prolong or halt. It is now necessary to evaluate your heat trace requirements. Keep the water flowing at low ambient temperatures with industrial pipe tracing. Use Nelson snow melting systems to prevent snow and ice accumulation on driveways, sidewalks, loading ramps, and other paved surfaces. Finally, don't forget about the roof and gutter de-icing products, which prevent the formation of ice dams on roofs, gutters, and downspouts anywhere.

Emerson's Nelson Heat Trace solutions combine conventional heat trace design ideas with cutting-edge installation, control, and monitoring technology to create a more efficient and reliable system. Our solutions are ideal for ensuring that metal pipes or other exposed equipment operate at the appropriate temperature. It is vital to maintain your equipment operational in the face of unpredictable weather circumstances; we provide complete environmental covering, no matter what the weather throws at you.

Ives Equipment

610-768-1600

https://ivesequipment.com

The Weather is Changing. Freeze Protect Your Facility Now!

Ensure frigid temperatures don’t slow you down.

Nelson Electric Heat Trace.

LEARN MORE HERE

An Energy Savings Solution for Domestic Hot Water in Hospitals, Hotels, Campuses, Governmental Facilities and Correctional Institutions

|

| The Smart System: Perfectly heated water – no hot spots, no burnouts, no recirculation. |

Self-regulating capabilities, environmental safeguards and a solid design make self-regulating technology the wisest choice, consistently maintaining your water supply at a prescribed temperature. The heating cable is fastened directly to the pipes, running their full length and creating a symbiotic relationship, which allows the cable to gauge any changes in water temperature. Sensing a decrease or increase in temperature, the conductive core then adjusts its own power output in response, and produces a consistent flow of perfectly heated water – no hot spots, no burnouts, no recirculation. The cable is designed to sustain nominal hot water temperatures of 105°F, 115°F, 125°F or 140°F.

Ives Equipment

www.ivesequipment.com

Philadelphia, PA: 610-768-1600

Baltimore, MD: 877-281-5678

York, PA: 717-227-1580

Washington, DC: 877-281-5678

Richmond,VA: 877-281-5678

Don't Risk Equipment or Safety: Freeze Protect Your Plant Now

|

| Don't let this happen at your plant. |

Main Categories for Industrial Heat Tracing

- Industrial Pipe Tracing Cable

- Industrial Tank and Vessel Heating

- Industrial Snow Melting

- Industrial Roof Gutter Deicing

Responsible facility management includes protecting buildings and equipment against freeze damage. There are many items in any given manufacturing plant to protect, including piping systems, process instrumentation, holding tanks, transfer vessels, and valves. For each of these items, there's a good freeze protection solution to be applied. Here are some of the more common heat tracing products used in these applications.

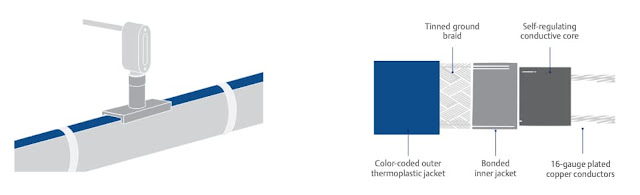

Self-regulating Heat Tracing Cable

These self-regulating, cut-to-length cables are normally installed in commercial and light industrial applications, to maintain pipe temperature and/or prevent freezing. These heating cables are available in 120 and 240 voltages and are designed for use in ordinary or hazardous locations (with proper selections and application). Typical applications for this product are freeze protection and low watt density process temperature systems such as product pipelines, fire protection, process water and dust suppression systems.

These self-regulating, cut-to-length cables are normally installed in commercial and light industrial applications, to maintain pipe temperature and/or prevent freezing. These heating cables are available in 120 and 240 voltages and are designed for use in ordinary or hazardous locations (with proper selections and application). Typical applications for this product are freeze protection and low watt density process temperature systems such as product pipelines, fire protection, process water and dust suppression systems.

Constant Wattage Heat Tracing Cable

Constant Wattage Heat Tracing Cable

Constant wattage heater cable is ideal for use in maintaining fluid flow under low ambient conditions. The product is used for freeze protection and process temperature maintenance systems such as product pipelines, process water, dust suppression systems, lube oil and condensate return.MI (Mineral Insulated) Cable

MI Cable is a metal sheathed cable that uses a metallic conductor as the heating element. It is custom designed and fabricated for specific applications. MI Cable is a high performance, industrial grade heat tracing cable used for applications requiring high temperature exposure, immunity to stress corrosion, high maintain temperature, under tank heating (cryogenic tanks), high power output, constant power output over entire, rugged cable construction heater length, and extended heater life.It is critical to consider the specific application requirements for any heat tracing application. The following checklist always needs to be clearly understood:

- The mass and material of the item being traced

- Insulation availability - type and thickness

- Temperature to be maintained

- Minimum ambient temperature

- Minimum start-up temperature

- Available supply voltage

- The chemical environment - expose

- Maximum intermittent exposure temperature

- Electrical area classification

Basic Information for the Design and Selection of Heat Trace Products for Pipe and Vessel Heating

|

| Heat Tracing Self-Regulating Cable |

It is always recommended to use thermal insulation since heat loss from bare surfaces is very high and heat transfer between the heater and the pipe/vessel is highly variable. All insulation should be weatherproofed. Wet insulation is ineffectual and heater output is insufficient to dry it.

- Variable Output

- Self-Regulating heaters will react to variations in temperature encountered at every point along its length. Colder sections receive more heat output, while warmer sections receive less. This provides greater energy efficiency and more uniform pipe temperatures.

- Can Be Overlapped Without Damage

- Because Self-Regulating heaters controls its own output, overlapped sections produce less heat, eliminating “hot spots” and possible burn-through common with other types of cable.

- Fail Safe

- Upon reaching the upper limits of its temperature range, Self-Regulating heaters diminishes its own heat output to an insignificant level. This guarantees that maximum temperatures (T ratings) cannot be exceeded no matter what product is used in any application.

- Easy Installation

- Because of its infinite parallel path circuitry, Self-Regulating heaters can be cut to any length in the field without affecting the heat output or creating “dead zones”.

|

| Constant Wattage Heat Tracing Cable |

Constant Wattage Heater Cable is a parallel resistance heater that produces the same watts-per-foot of heat along its entire length.

- EasyInstallation

- Constant-Wattage heaters can be cut to length and terminated in the field.

- Economical

- Provides good power densities and exposure temperatures with parallel circuit cable capabilities at economical prices. Exposure Temperatures to +204°C (+400°F). Ideal for maintaining many process temperature applications.

|

| MI Cable |

Mineral insulated Cable is a series conductor, high temperature heater cable with a special, thin metal sheath. Some of MI advantages are:

- Corrosion-Resistant

- Alloy 825 sheath provides excellent corrosion resistance and immunity from chloride stress corrosion - a common problem with stainless steel.

- Ideal for High Temperature Applications

- Mineral Insulated heaters can withstand exposure temperatures up to 593°C (1100°F). Exposure temperatures can be increased to 750°C (1400°F) with special components.

- Ratings To 600V

- Mineral Insulated heaters are available in a variety of voltages to match the available power supply.

- High Heat Output

- Mineral Insulated heaters have heat output ratings up to 10 times higher than most other cables, reducing the amount of cable required.

- Rugged Construction

- A durable metal sheath provides greater mechanical protection.

- Thin Wall Construction

- A unique manufacturing process allows thin wall cable construction for easier field installation.

|

| Heating Panel |

- Low Cost Installation

- Flexible silicone construction allows panel to conform to tank wall. No bonding or heat transfer aids are required.

- High Temperature

- Tank Heating Panels maintain temperatures up to 79°C (175°F) and can withstand exposure to 204°C (400°F).

Basics of Self-Regulating Heat Trace Cable

|

| Self-regulating Heat Tracing Layout |

Principle of Operation:

The parallel bus wires apply voltage along the entire length of the heater cable. The conductive core provides an infinite number of parallel conductive paths permitting the cable to be cut to any length in the field with no dead or cold zones developing. The heater cable derives its self- regulating characteristic from the inherent properties of the conductive core material. As the core material temperature increases, the number of conductive paths in the core material decreases, automatically decreasing the heat output. As the temperature decreases, the number of conductive paths increases, causing the heat output to increase. This occurs at every point along the length of the cable, adjusting the power output to the varying conditions along the pipe. The self-regulating effect allows the cable to be overlapped without creating hot spots or burnout. As the cable self-regulates it heat output, it provides for the efficient use of electric power, producing heat only when and where it is needed, and also limiting the maximum surface temperature.

Application:

Self-regulating heater cable is ideal for use in maintaining fluid flow under low ambient conditions. Freeze protection and low watt density process temperature systems such as pipelines, fire protection, process water, dust suppression systems, hot water and structure anti-icing are typical applications for this product. For other than metal pipe heating, see appropriate application guide. The base product is supplied with a copper metal braid with a thermoplastic elastomer overjacket for wet applications, exposure to the sun, and where mechanical abuse is a problem. Cables are UL Listed and CSA Certified for use in non-hazardous locations and can be used on branch sprinkler systems.

For more information see the following Nelson Electric product sheet.