|

| Don't let this happen at your plant. |

Winter is here in its full glory. Plant engineers and plant maintenance have to pay special care in

preventing freezing in pipelines, tanks, Vessels, conveyors, and impulse lines. The cold temperatures in the Mid-Atlantic can often damage or destroy process equipment and it's valuable contents. Most commonly, pipes, instrumentation, and valves are the vulnerable items affected by the sudden drop in temperatures, causing devastating consequences, including costly downtime and unplanned outages. But there's also safety issues to be considered with snow and ice build up, so attention must be paid to snow and ice melting.

Main Categories for Industrial Heat Tracing

- Industrial Pipe Tracing Cable

- Industrial Tank and Vessel Heating

- Industrial Snow Melting

- Industrial Roof Gutter Deicing

Responsible facility management includes protecting buildings and equipment against freeze damage. There are many items in any given manufacturing plant to protect, including piping systems, process instrumentation, holding tanks, transfer vessels, and valves. For each of these items, there's a good

freeze protection solution to be applied. Here are some of the more common heat tracing products used in these applications.

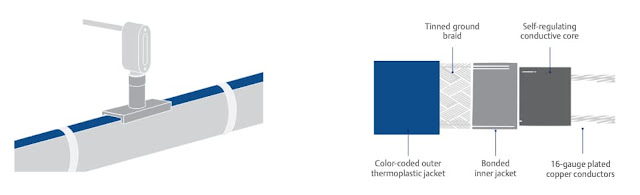

Self-regulating Heat Tracing Cable

These self-regulating, cut-to-length cables are normally installed in commercial and light industrial applications, to maintain pipe temperature and/or prevent freezing. These heating cables are available in 120 and 240 voltages and are designed for use in ordinary or hazardous locations (with proper selections and application). Typical applications for this product are freeze protection and low watt density process temperature systems such as product pipelines, fire protection, process water and dust suppression systems.

Constant Wattage Heat Tracing Cable

Constant Wattage Heat Tracing Cable

Constant wattage heater cable is ideal for use in maintaining fluid flow under low ambient conditions. The product is used for freeze protection and process temperature maintenance systems such as product pipelines, process water, dust suppression systems, lube oil and condensate return.

MI (Mineral Insulated) Cable

MI Cable is a metal sheathed cable that uses a metallic conductor as the heating element. It is custom designed and fabricated for specific applications. MI Cable is a high performance, industrial grade heat tracing cable used for applications requiring high temperature exposure, immunity to stress corrosion, high maintain temperature, under tank heating (cryogenic tanks), high power output, constant power output over entire, rugged cable construction heater length, and extended heater life.

It is critical to consider the specific application requirements for any heat tracing application. The following checklist always needs to be clearly understood:

- The mass and material of the item being traced

- Insulation availability - type and thickness

- Temperature to be maintained

- Minimum ambient temperature

- Minimum start-up temperature

- Available supply voltage

- The chemical environment - expose

- Maximum intermittent exposure temperature

- Electrical area classification