- Identifying Customer Needs: A skilled technical sales team possesses the knowledge and expertise to understand complex industrial systems. They can work closely with customers, identifying their specific requirements and challenges, thereby offering tailored solutions that best address their needs. This consultative approach builds customer trust and strengthens long-term relationships.

- Supporting Business Growth: Technical sales teams drive sales and revenue growth by providing appropriate and optimal solutions to customers. They actively seek out new opportunities and target prospective customers with offerings that match their unique needs. Their in-depth understanding of the technology enables them to align the company’s products and services with diverse industrial sectors' current and future requirements.

- Uncovering New Markets and Applications: A highly qualified technical sales team excels in discovering new markets and application areas where their products and services can create value. By leveraging their industry expertise, these sales professionals identify new opportunities and help expand the reach of their products into untapped markets. In doing so, they contribute significantly to the company’s growth strategy.

- Delivering Product Expertise: Industrial process control instrumentation and industrial valves can be complex products requiring high technical knowledge. Sales teams specializing in these products deeply understand their specifications, applications, and benefits. They can explain the intricacies of these products, helping customers make informed purchasing decisions.

- Providing Post-Sales Support: A qualified technical sales team doesn’t just close deals; they provide valuable post-sales support. Whether it’s assisting with installation, troubleshooting technical issues, or training the customer’s staff, these professionals ensure the smooth integration of their products into the customer’s operations. This service fosters customer loyalty and encourages repeat business.

- Mitigating Market Risks: In volatile industries such as petrochemical and power generation, changes in regulations, technology, and market demand can create uncertainties. A proficient technical sales team keeps abreast of industry trends and regulatory changes. They help their organization adapt to these shifts by offering products and solutions that align with the changing market landscape.

- Accelerating Innovation: Technical sales teams act as a bridge between the company and its customers. They collect feedback from customers regarding product performance, needs, and challenges. This feedback helps the company’s R&D team develop innovative products and solutions that meet emerging industry needs.

- Enhancing Customer Satisfaction: By providing tailored solutions, excellent customer service, and reliable support, a qualified technical sales team enhances customer satisfaction. Satisfied customers become brand advocates, leading to increased referrals and new business opportunities.

Educational information on process control, industrial instrumentation, valves, valve automation and control valves. For additional information visit IvesEquipment.com or call 877-768-1600

The Critical Role of Qualified Technical Sales Organizations in Industrial Process Control

Automation and Control Solutions for Hydrogen Production and Alternative Energy

Seven Decades of Commitment, Service, and Expertise in Process Control

For almost 70 years, Ives Equipment Corporation has provided the industries of eastern and central Pennsylvania, Delaware, Maryland, metro NY, New Jersey, Virginia, and Washington DC with the most up-to-date process control equipment as well as process control consulting and services.

Ives established their company on a foundation of high-quality employees that are well-trained and experienced and who are passionate about finding the most effective solutions to their clients' control challenges.

Ives categorizes its comprehensive product portfolio under four distinct groups. These are as follows:

Ives Equipment and Controls: Provides instrumentation and control products to the chemical, petrochemical, refining, bulk storage, primary metals, pulp & paper, PowerGen, gas & oil distribution, and OEM markets.

Pharmaceutical, Bio-pharm, and Sanitary: Provides hygienic, ultra-pure, and sanitary instruments, connectors, fittings, tubing, and gaskets to the pharma, bio-pharm, food, and beverage, life-science, and laboratory industries.

Analytical Instruments: Analyze process material samples and record data for quality, conformance, and compliance.

Water and Wastewater Treatment: Providing instruments, analyzers, valves, and controls for the transfer, storage, analysis, treatment, and logging of municipal and industrial water treatment systems.

The most successful path is one that provides you with the answers and expertise you require, when and where you need it, and from a single source. Ives Equipment will assist you in streamlining operations and establishing a single point of responsibility, supported by industry experience and the application expertise you require. Let Ives Equipment provide you with that significant competitive advantage.

Understanding HART Communication Protocol

Looking at a standard loop-powered (2-wire) process transmitter circuit, we see the transmitter, a DC power supply (voltage source), and usually a 250 ohm resistor to create a 1 to 5 volt signal readable by any voltage-sensing indicator, controller, or recorder:

The transmitter’s primary function in this circuit is to regulate current to a value representative of the measured process variable (e.g. pressure, temperature, flow, etc.) using a range of 4 to 20 mA, while the DC voltage source provides power for the transmitter to operate. Loop-powered instruments are very common in industrial instrumentation because they allow both power and (analog) data to be conveyed on the same pair of wires.

With the advent of microprocessor-based process transmitters, it became possible for instrument technicians to digitally configure parameters inside the transmitter (e.g. range values, damping values) and also query the transmitter for self-diagnostic alarms. In order to make full use of this digital functionality, though, there had to be some way to communicate digital data to and from the process transmitter over the same two wires used to convey the 4-20 mA analog signal. Otherwise, the only way to access this rich array of digital data inside the transmitter would be to connect a communicator device to some data port located on the transmitter itself, which is inconvenient due to the nature of how these transmitters are used in industry (located in dirty places, often hard to access while carrying a personal computer or other communication device).

|

| HART Transmitter (Siemens) |

Thus the HART communication protocol was born to address this need. HART communicates digital data along the loop conductors in the form of AC signals (audio-frequency tones) superimposed on the 4-20 mA DC current signal. A modem built into the smart transmitter translates these AC signals into binary bits, and vice-versa. Now, instrument technicians could “talk” with the new microprocessor-based transmitters simply by connecting a HART communications device at any point along the two-wire cable, even at the far end where the cable terminates at the control system hardware (panel-mounted controller, PLC, DCS, etc.).

Being able to communicate digital data over the same wire pair as the DC power and analog signal opens a whole new range of possibilities. Now, the field-mounted transmitter can communicate self-diagnostic information, status reports, alarms, and even multiple process variables to the control system in addition to the original analog signal representing the (main) process variable. With digital communication, the only data limitation is speed (data rate), not quantity. The control system may even communicate information to the transmitter using the same digital protocol, using this digital data channel to switch between different measurement range sets, activating special features (e.g. square-root characterization, damping, etc.), automatically and remotely.

Reprinted from "Lessons In Industrial Instrumentation" by Tony R. Kuphaldt – under the terms and conditions of the Creative Commons Attribution 4.0 International Public License.

Differential Pressure Transmitters and Inferential Measurement

|

| Differential Pressure Transmitter (Siemens) |

An example of inferential measurement via DP transmitter is the way in which the height of a vertical liquid column will be proportional to the pressure generated by gravitational force on the vertical column. The differential pressure transmitter measures the pressure exerted by the contained liquid. That pressure is related to the height of the liquid in the vessel and can be used to calculate the liquid depth, mass, and volume. The gravitational constant allows the pressure transmitter to serve as a liquid level sensor for liquids with a known density. A true differential pressure transmitter also enables liquid level calculations in vessels that may be pressurized.

Gas and liquid flow are two common elements maintained and measured in process control. Fluid flow rate through a pipe can be measured with a differential pressure transmitter and the inclusion of a restricting device that creates a change in fluid static pressure. In this case, the pressure in the pipe is directly related to the flow rate when fluid density is constant. A carefully machined metal plate called an orifice plate serves as the restricting device in the pipe. The fluid in the pipe flows through the opening in the orifice plate and experiences an increase in velocity and decrease in pressure. The two input ports of the DP transmitter measure static pressure upstream and downstream of the orifice plate. The change in pressure across the orifice plate, combined with other fluid characteristics, can be used to calculate the flow rate.

Process environments use pressure measurement to inferentially determine level, volume, mass, and flow rate. Using one measurable element as a surrogate for another is a useful application, so long as the relationship between the measured property (differential pressure) and the inferred measurement (flow rate, liquid level) is not disrupted by changes in process conditions or by unmeasured disturbances. Industries with suitably stable processes - food and beverage, chemical, water treatment - are able to apply inferential measurement related to pressure and a variable such as flow rate with no detectable impact on the ability to measure important process variables.

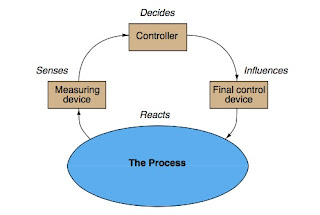

Introduction to a Closed Loop Control System

|

| Closed Loop Control System |

A closed loop control system uses a sensor that feeds current system information back to a controller. That information is then compared to a reference point or desired state. Finally, a a corrective signal is sent to a control element that attempts to make the system achieve its desired state.

A very basic example of a temperature control loop includes a tank filled with product (the process variable), a thermocouple (the sensor), a thermostat (the controller), and a steam control valve feeding a tubing bundle (the final control element).

The video outlines all the major parts of the system, including the measured variable, the set point, the controlled variable, controller, error and disturbance.

Contact http://www.ivesequipment.com with any process control or instrumentation requirement. Call 877-768-1600 for immediate assistance.

Ives Equipment Business Groups

Ives Equipment and Controls, providing instrumentation and control products to the chemical, petro-chemical, refining, bulk storage, primary metals, pulp & paper, powergen, gas & oil distribution and OEM markets.

Pharmaceutical, Bio-pharm, and Sanitary, providing hygienic, ultra-pure and sanitary instruments, connectors, fittings, tubing and gaskets to the pharma, bio-pharm, food and beverage, life-science and labortory industries.

Analytical Instruments, used to analyze process material samples and record the data for quality, conformance and compliance.

Water and Wastewater Treatment, providing instruments, analyzers, valves and controls for the transfer, storage, analysis, treatment, and logging of municipal and industrial water treatment systems.

Upgrading to a United Electric (UE) Controls One Series from a Mechanical Pressure Switch

This video below demonstrates how to replace an older on/off mechanical pressure switch and install the UE One Series.

This video below demonstrates how to replace an older on/off mechanical pressure switch and install the UE One Series.The One Series electronic pressure and temperature transmitter-switches set the standard for smart digital process monitoring. With a fully adjustable set point and deadband and 0.1% repeatability, the One Series performs in a wide variety of applications. Available in Type 4X enclosures approved for intrinsic safety, flameproof and non-incendive area classifications, these hybrid transmitter-switches are designed to provide transmitter, switch and gauge functions all-in-one rugged enclosure that can withstand the rigors of harsh and hazardous environments.

Each One Series model incorporates intelligent self-diagnostics and can report detected faults before they become major safety issues. Plug Port Detection protects against sensor clogging. Nuisance trip filtering reduces false and spurious signals. The ability to capture pressure spikes and valleys provides process information to aid in the commissioning and debugging process.

For more information, visit http://www.ivesequipment.com or call (877) 768-1600.

Advanced Safety Integrity Universal Gas Transmitter

SensAlert ASI is third-party certified to IEC61508 Level 2 (SIL-2) for both hardware and software with certification to global hazardous area and performance standards. The Test-on-Demand feature with on-board gas generator provides remote functionality checks with generated gas while Predictive Sensor End-of-Life Indication provides advanced warning of impending sensor failure.

Instrumentation and Controls for the Grain Industry

|

| Instruments and control for grain producers. |

Working with grain has the potential to be deadly, especially when grain is in motion. Similar to ‘quicksand,’ moving grain can bury a worker in seconds. In 2010, U.S. grain operators reported that fifty-one workers had been trapped in grain, more than in any year since Purdue University began collecting data on grain entrapments in 1978. Sadly, almost half of these entrapments led to fatalities.

Increasing automation

Another reason for the push towards automation is that owners are constantly looking to increase production and reduce expenses while still producing a high quality product. A solution is to invest in automated processes in a facility. Many facilities have moved to complete automation of production, termed Totally Integrated Automation (TIA).

Refining inventory management

Tracking inventory in grain silos is a significant component of a successful grain operation. Managing raw materials and finished products is essential for keeping processes efficient and optimizing inventory ordering and shipments. By knowing where materials are located, companies can use these resources more effectively, decreasing human intervention and increasing efficiency. As well, checking bin levels on a regular basis requires substantial labor costs. To make inventory track-ing faster and more streamlined, the industry is continually moving towards automated inventory management.

New Ives Equipment Video

For more than 60 years, Ives Equipment Corporation has successfully served the industries of eastern and central Pennsylvania, Delaware, Maryland, metro NY, New Jersey, Virginia and Washington DC with the latest in process control equipment and services.

The Ives business is built on a foundation of quality people, highly trained and experienced, who take a keen interest in finding the optimum solutions to customers' control problems.

Industrial Control Valve Actuator Operating Principles

The valve actuator is the component that physically moves the restrictor to vary the fluid flow. Three actuator types are used in control valves and they include spring and diaphragm, solenoid, and motor. As the name suggests the spring in diaphragm actuator uses a spring and a diaphragm to move the valve stem and plug.

A 15 PSI pneumatic signal enters the housing at the top of the actuator. As pressure is exerted on the diaphragm a downward force is applied against the spring which moves the restrictor. The diaphragm moves until it creates an equal but opposing force against the spring at which time the motion stops as the plug meets the valve seat. With no air pressure the restrictor is pushed upward by the spring to act as a normally open control valve. To vary the position of the restrictor and flow through the valve, a current to pressure transducer can be used to provide a three to 15 PSI signal to the diaphragm. At 3 PSI the valve is maintained open, and 15 PSI the valve is maintained closed. Pressures between the three to 15 PSI range proportionally change the flow of the valve. For example a pressure of 9 PSI applied to the diaphragm moves the spring and valve stem to 50 percent operating range.

For on /off control of the valve, a solenoid is used to actuate the valve to a fully closed or fully open position. Applying current to the coil generates a magnetic field that moves the plunger downward against the return spring. With zero current applied to the coil the spring pulls the plunger upwards to the fully open position for a normally open state control valve.

Another method for variable valve positioning uses a motor and is referred to as proportional control mode. Using a gear motor attached to the valve stem a servo amplifier provides a DC control signal that moves the valve to the desired position. Feedback is achieved with the wiper arm attached to the valve stem that sends a signal back to the servo amplifier where the position is monitored the servo amplifier drives the motor until the control signal is equal to the feedback signal.

Watch the video below for an illustrated explanation. For more information on control valves, contact Ives Equipment at 877-768-1600 or visit http://www.ivesequipment.com.

Your Plant's Partners Make A Huge Difference in Performance and Profitability

The Ives business is built on a foundation of quality people, highly trained and experienced, who take a keen interest in finding the optimum solutions to customers' control problems. If you need a proven, experienced, and reliable business partner, choose Ives.

PART 1: Setting Up and Operating the United Electric One Series Safety Transmitter

|

| One Series Safety Transmitter |

The One Series Safety Transmitter is a pressure or temperature monitoring transmitter switch that provides a NAMUR NE 43 standard 4-20 mA analog output. Its programmable high-capacity solid-state safety relay output enables the fastest emergency shutdowns.

The One Series Safety Transmitter is certified for use in SIL 2 functional safety applications (HFT = 0), and is capable of SIL 3 applications when augmented by redundancy and voting logic. Its simple design means fewer nuisance trips — for greater safety, productivity, and throughput.

The One Series Safety Transmitter was designed with features that simplify installation, improve productivity, and eliminate nuisance trips. “I Am Working” sensor diagnostics with redundant data processing detect open, shorted, and plugged sensing elements.

The transmitter’s analog output conforms to the NAMUR NE 43 standard and provides process variable (PV) and detected-fault information. Discrete outputs provide a fail-safe (open) emergency shutdown when a fault is detected. Set point and deadband (reset point) are 100% programmable.

The instrument is password protected to prevent unwanted parameter changes; eliminating the risk of tampering. In addition, LED backlighting enhances viewing of process variables, parameters, and status in dimly lit areas.

- Fewer nuisance trips for greater productivity

- More affordable than adapting a process transmitter for SIS

- Internal relay for faster emergency shutdowns

- Higher safe failure fraction simplifies SIL achievement

For more information, contact:

PART 2: Setting Up and Operating the United Electric One Series Safety Transmitter

|

| One Series Safety Transmitter |

The One Series Safety Transmitter is a pressure or temperature monitoring transmitter switch that provides a NAMUR NE 43 standard 4-20 mA analog output. Its programmable high-capacity solid-state safety relay output enables the fastest emergency shutdowns.

The One Series Safety Transmitter is certified for use in SIL 2 functional safety applications (HFT = 0), and is capable of SIL 3 applications when augmented by redundancy and voting logic. Its simple design means fewer nuisance trips — for greater safety, productivity, and throughput.

The One Series Safety Transmitter was designed with features that simplify installation, improve productivity, and eliminate nuisance trips. “I Am Working” sensor diagnostics with redundant data processing detect open, shorted, and plugged sensing elements.

The transmitter’s analog output conforms to the NAMUR NE 43 standard and provides process variable (PV) and detected-fault information. Discrete outputs provide a fail-safe (open) emergency shutdown when a fault is detected. Set point and deadband (reset point) are 100% programmable.

The instrument is password protected to prevent unwanted parameter changes; eliminating the risk of tampering. In addition, LED backlighting enhances viewing of process variables, parameters, and status in dimly lit areas.

The Series One leads the market in process safety transmitters because:

- Fewer nuisance trips for greater productivity

- More affordable than adapting a process transmitter for SIS

- Internal relay for faster emergency shutdowns

- Higher safe failure fraction simplifies SIL achievement

Common Areas to Find Fluid Control Valves in Wine Production

|

| Valves and controls play big role in wine quality |

A variety of fluid control valves are commonly used in the production of wine, both large scale production and smaller scale. These valves are found in many areas, from sanitary valves handling the product itself, to hot water valves for cleaning equipment, to pneumatic valves transmitting pneumatic signals to handling equipment.

Here is a quick video showing some typical areas where fluid control valves can be found in the wine making process.

For more information, contact:

Ives Equipment

www.ivesequipment.com

877-768-1600

Industrial Temperature Sensors: Basics of Thermocouples

|

| Industrial thermocouples (courtesy of Applied Sensor Technology) |